Win-win solution for pharmaceutical factory in Romania

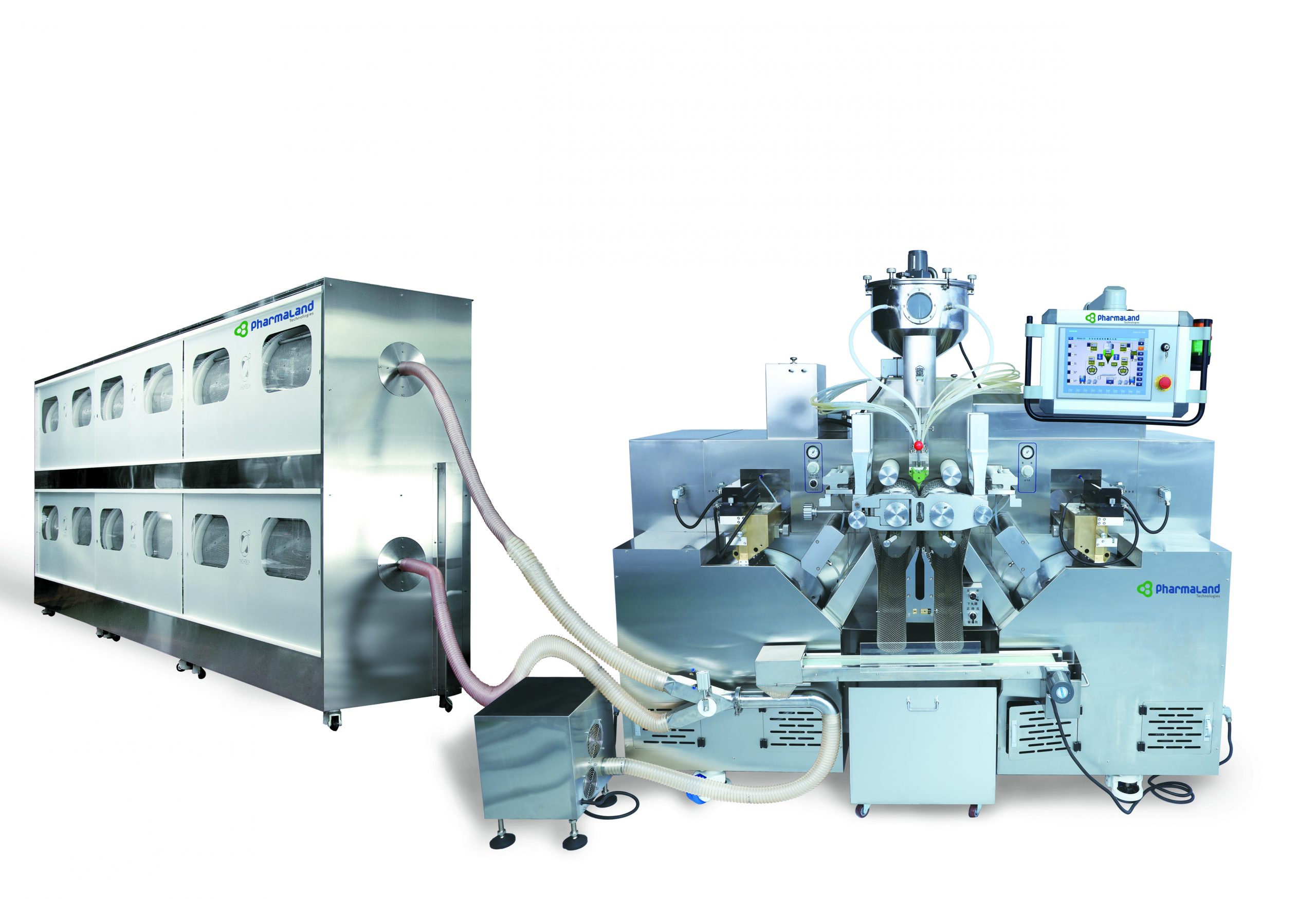

Machines in the project: A fully automated production line, including a coating machine, tablet press machine, filling machine, mixing machine and blister packing line. In 2016, Pharmaland met a prospective new client from Romania, who was a newcomer to the industry, who was skeptical about......

17 April, 2022 No comment