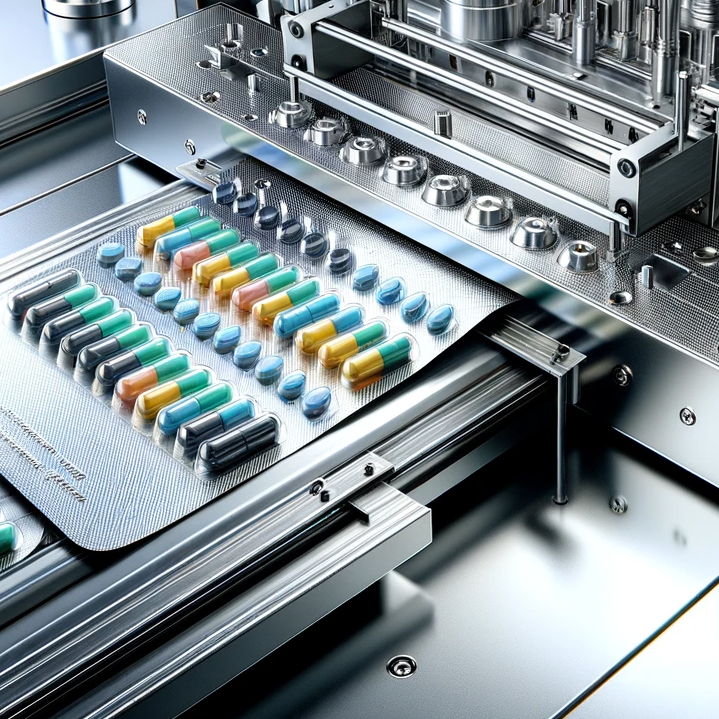

06 Jun Key Features and Advantages of Modern Blister Packing Equipment

In the rapidly evolving sectors of pharmaceuticals, healthcare, food, cosmetics, and medical equipment, the significance of efficient, reliable packaging solutions cannot be overstated. Modern blister packing equipment stands at the forefront of this requirement, incorporating advanced technologies to ensure product safety, compliance with Good Manufacturing Practice (GMP) standards, and operational efficiency. This article delves into the key features and advantages of contemporary blister packing machinery, highlighting their indispensable role in today’s manufacturing landscape.

Understanding Blister Packing Machine

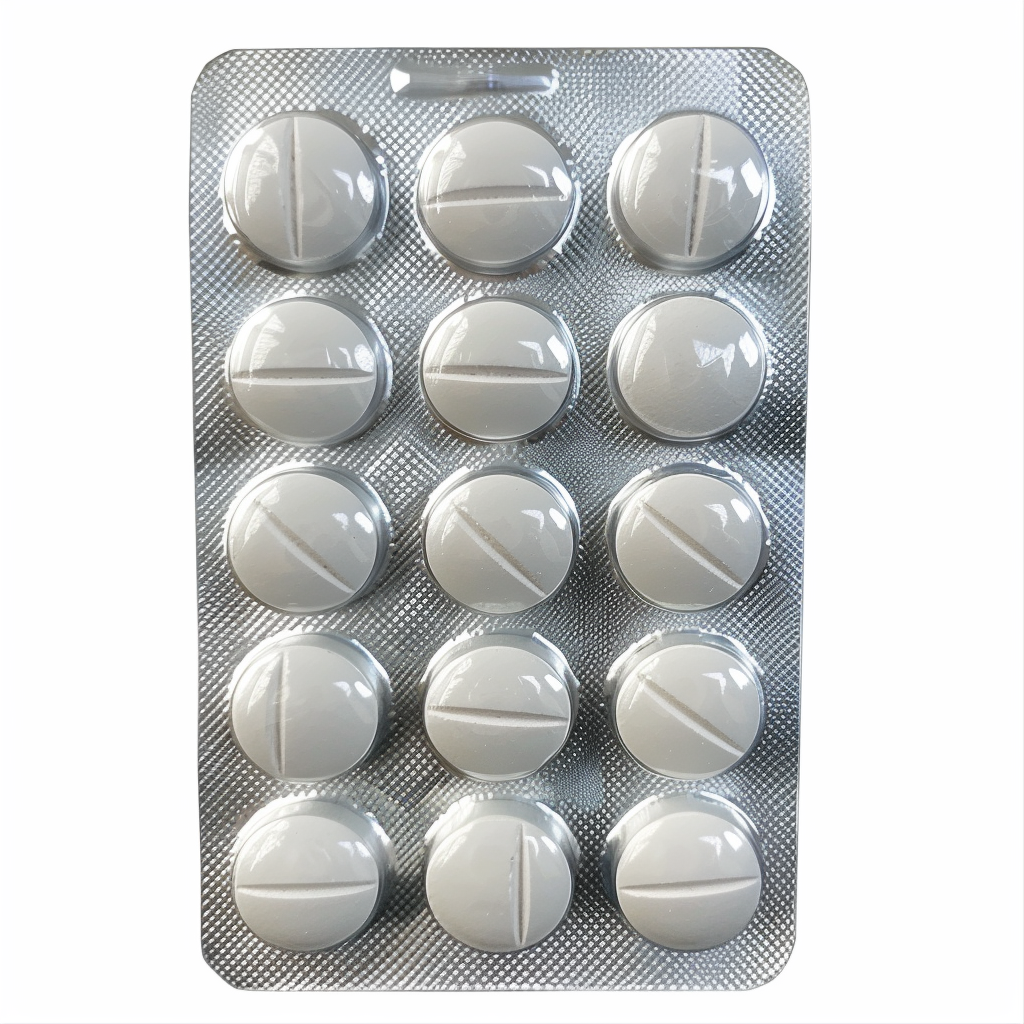

Blister packing machines are specialized equipment designed to package products in a cavity or blister, sealed with a backing material, usually aluminum foil or plastic. This packaging method not only extends the shelf life of products but also offers a tamper-evident seal, enhancing consumer trust and safety. Blister packs are particularly prevalent in the pharmaceutical industry, where product integrity is paramount.

Key Features of Modern Blister Packing Equipment

Variable Frequency Speed Regulation

Modern machines utilize servo traction for variable frequency speed regulation, allowing for precise control over the packaging speed and stroke adjustment. This flexibility ensures that blister packs are formed consistently and efficiently, accommodating different product sizes and specifications.

Push-Stepping Mechanism

This mechanism enables the smooth formation of blisters and facilitates easy adjustments for various product dimensions, further enhancing the versatility and efficiency of the packaging process.

Advanced Molding and Sealing

Equipped with plate-type mold positive-pressure forming, modern blister packing machines feature integrated batch number printing, creasing, and cutting functionalities. This consolidation of processes not only improves efficiency but also ensures that each pack meets stringent quality standards.

High Filling Accuracy

The inclusion of a general feeder with a filling accuracy of 99.5% or higher addresses common challenges associated with product wastage and inconsistency. Additionally, the feeder’s dust exhaust joint significantly mitigates dust-related issues during the filling process.

Efficient Heating System

Adopting a registering matching heating system, modern equipment minimizes heat energy loss, reducing operational costs and environmental impact. This system ensures that the required sealing temperatures are quickly achieved and maintained, promoting energy efficiency.

PLC Control and Frequency Adjustment

The integration of PLC control systems offers broad adjustment ranges and simplifies the operation and maintenance of the machinery. This feature, coupled with frequency adjustment capabilities, contributes to a quieter, more user-friendly working environment.

Advantages of Using Modern Blister Packaging Machine

Improved Product Integrity and Safety

The advanced sealing and packaging technologies of modern blister packing machines play a crucial role in protecting products from contamination, tampering, and damage, thereby ensuring their integrity and safety.

Enhanced Operational Efficiency

With features like servo-driven speed control and automated feeding systems, these machines significantly reduce downtime and increase production rates, leading to higher throughput and reduced operational costs.

Compliance with GMP Standards

Modern blister packing equipment is designed with GMP compliance in mind, featuring fully-enclosed structures and high-quality stainless steel contact materials, ensuring that products are manufactured in a clean, safe environment.

Versatility in Packaging

The ability to accommodate a wide range of products, materials, and irregular shapes makes modern blister packing machines highly versatile, enabling their use across various industries beyond pharmaceuticals, including food and cosmetics.

Understanding Blister Packaging Machines

Blister packaging machines are designed to securely package products into blisters, accommodating a wide range of items including pharmaceutical capsules, medical devices, and food products. These machines are categorized into semi-automatic blister packaging machines and automatic blister packaging machines, each offering unique benefits and functionalities to fit various production demands and scales.

Semi-Automatic Blister Packaging Machines

Semi-automatic blister packaging machines provide users with greater flexibility and control, making them ideal for small-scale production and testing new products. These models typically require operators to manually place products into blisters, after which the machine completes the sealing process. While slower than fully automatic models, they offer additional convenience in adjusting and switching between different products.

Automatic Blister Packaging Machine

Automatic blister packaging machines significantly enhance packaging efficiency and consistency by reducing manual intervention and increasing production speed. Capable of seamlessly executing the entire process from product filling, blister forming, to sealing and cutting, they are suited for medium to large-scale production needs. Automatic models are usually equipped with advanced control systems and sensors to ensure precision and product quality.

Real-world Applications and Customer Feedback

Industry feedback underscores the reliability, ease of use, and efficiency of modern blister packing equipment. Customers often highlight the professional support received from manufacturers, the straightforward maintenance, and the significant improvements in packaging quality and consistency.

Conclusion

The advent of modern blister packing equipment has heralded a new era in manufacturing, offering unparalleled efficiency, safety, and compliance. By choosing the right equipment, businesses can ensure their products are not only protected but also presented in a way that meets the high expectations of today’s consumers.

FAQs

Q: Can blister packing machines handle different types of materials? A: Yes, modern machines are designed to work with a variety of packaging materials, including PVC, PTP (Press Through Packaging), and dialysis paper, among others.

Q: How do I know which model is suitable for my production needs? A: Manufacturers can provide guidance based on your specific product dimensions, material requirements, and production volume, ensuring you select the most appropriate model.

Q: Can blister packing equipment be integrated with other machinery? A: Yes, many modern machines offer integration capabilities with cartoning machines and other packaging equipment, streamlining the packaging process further.