02 Sep What to Ask Before Investing in a Capsule Filling Machine ?

Introduction

Capsule filling machines have revolutionized the pharmaceutical and health supplement industries by streamlining the encapsulation process. These machines, varying from manual to semi-automatic and fully automatic models, cater to a broad range of production needs. The importance of making an informed decision cannot be overstated, as the right capsule filling machine can significantly impact production efficiency, accuracy, and long-term cost savings. This introduction sets the stage for a detailed examination of what potential buyers should consider before investing in a capsule filling machine, including the key benefits of enhancing production capabilities with such a device.

Why Invest in a Capsule Filling Machine?

Investing in a capsule filling machine is a strategic decision for businesses aiming to scale their production of capsules. The capsule machine not only improves production efficiency but also ensures the accuracy of the dosage. Moreover, in the long run, the reduction in labor and waste leads to considerable cost savings. Whether for pharmaceuticals or dietary supplements, the ability to rapidly and accurately fill capsules with powders, including active ingredient like microcrystalline cellulose or magnesium stearate, can be a game-changer. These high-quality excipients are designed to facilitate easy flowing powder and encapsulation, making the creation process easier and ensuring the product’s integrity.

Q&A Section

Q1: What Types of Capsule Filling Machines Are Available?

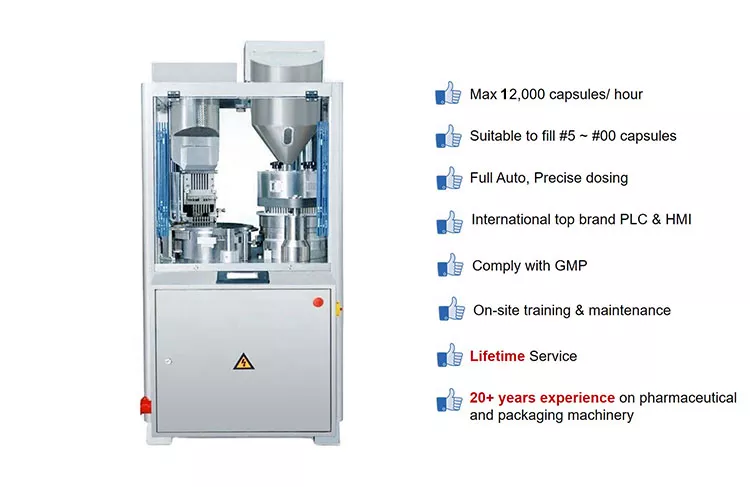

There are three main types of capsule filling machines: manual, semi-automatic, and fully automatic, each serving different production environments. Manual and semi-automatic machines are suitable for smaller operations or those with variable products, offering flexibility and lower initial costs. Fully automatic machines, on the other hand, are ideal for high-volume production, featuring advanced technologies that streamline the encapsulation process, reduce manpower, and enhance efficiency.

Q2: How Does the Machine’s Capacity Affect My Choice?

The capacity of the capsule filling machine largely determines its suitability for your operation’s volume. Assessing the machine’s capacity is crucial as it impacts your ability to meet production demands. Guidance on choosing the appropriate capacity involves understanding your current and future production needs and selecting a machine that can accommodate those requirements without unnecessary stress on the system.

Q3: What Should I Know About the Compatibility with Capsule Sizes and Types?

Compatibility with various capsule sizes and types is essential for a versatile production line. The machine should support the encapsulation of different ingredients, including active and inert substances like silicon dioxide and magnesium stearate, without compromising on efficiency. Checking for compatibility ensures that the machine can handle your specific production needs, including any unique formulations or capsule requirements.

Q4: What Are the Cleaning and Maintenance Requirements?

Maintenance and cleaning protocols are critical for keeping the capsule filling machine in optimal working condition. Different machines may have specific requirements for cleaning and maintenance, impacting production downtime and long-term usability. Ensuring that these tasks can be performed efficiently will help maintain production efficiency and prolong the machine’s lifespan.

Q5: Can the Machine Handle Multiple Products?

A capsule filling machine’s ability to handle multiple products and formulations is crucial for businesses that produce a variety of supplements. Machines designed with flexibility in mind can save time and reduce costs by facilitating quick changes between different products, encapsulating everything from easy flowing powders to more challenging ingredients.

Q6: What Is the Total Cost of Ownership?

Beyond the initial purchase price, the total cost of ownership of a capsule filling machine includes operation, maintenance, and potential upgrade costs. High-quality machines designed for constant improvement and compatibility with a range of excipients and active ingredients can reduce long-term costs and enhance production efficiency. Evaluating these costs ahead of time will help businesses make a financially sound investment.

Q7: How to Ensure the Capsule Machine Meets Specific Production Requirements?

When choosing a capsule filling machine, ensuring that the machine can handle your specific formulas and raw materials is crucial. This includes whether the machine can efficiently use excipients like silicon dioxide and magnesium stearate—ingredients that not only help absorb liquids but also ensure powder flowability. Verifying that the machine can easily process everything from easy-flowing powders to more challenging liquid ingredients is an indispensable step in formulating your own formula and streamlining your production process.

Q8: How to Improve Production Efficiency with a Capsule Filling Machine?

Just Like tablet pill press machine ,The key to enhancing production efficiency lies in selecting an encapsulation machine designed to handle a variety of production variables and raw materials. High-quality excipients designed not only to improve the flow qualities of powders but also to reduce friction between them ensure an even distribution during the capsule filling process. Additionally, the machine’s special design should include reducing unnecessary research and stress, thereby simplifying the creation process.

Q9: How Do Registered Users’ Reviews of the Capsule Machine Affect the Repeat Customer Base?

Feedback from only registered users is crucial for continuous improvement of the capsule filling machine. Encouraging customers to write their own review can provide valuable insights, helping manufacturers and sales assistants understand which features are most appreciated and which areas need improvement. A stable repeat customer base is usually a direct reflection of product satisfaction, which is often based on the machine’s reliability, efficiency, and user-friendliness.

Q10: How Does Bulk Pricing Influence the Purchase Decision for a Capsule Filling Machine?

Offering bulk pricing is key to attracting businesses that require large-scale production. This not only saves costs for the customer but can also bring in potential large orders for the manufacturer. When considering a purchase, customers require bulk pricing and look for suppliers who can offer competitive bulk quotes and high-quality excipients to ensure their production process is both economical and efficient. Sometimes , reduce trace quantities may cause a higher price .

Q11: What Impact Does Obtaining DEA(Drug Enforcement Administration (DEA)) Permission Have on Manufacturing Capsules Containing Controlled Substances?

For those planning to produce capsules containing active ingredients , especially those that may be classified as controlled substances, obtain DEA permission is a crucial step. This not only ensures the legality of the production process but also helps to build trust with customers. The appropriate DEA form must be filled out and all necessary clinical trials passed to ensure the safety and efficacy of the product.

Q12: How Does the Capsule Filling Machine Handle Liquid Ingredients and Improve the Flowability of Raw Ingredients?

The design of capsule filling machines typically considers how to turn liquid ingredients into a powder form that is easy to handle and how to enhance the flowability of powders by using flow agents like silica dioxide. Magnesium stearate, as a prime lubricant, ensures an even distribution of powder during the filling process while reducing friction and flow issues within the machine, thus enhancing the efficiency of the entire encapsulation process.

How to Choose the Right Supplier?

Selecting the right supplier for your capsule filling machine is a critical decision that can significantly impact your business’s operational efficiency and product quality. When evaluating potential suppliers, consider the following key factors:

-

After-Sales Service: Look for suppliers who offer comprehensive after-sales support. This includes maintenance services, parts replacement, and troubleshooting. The ability of silicon dioxide to absorb liquids and magnesium stearate to ensure powder flowability highlights the complexity of the materials involved. Thus, having a supplier who can provide timely and effective after-sales service is crucial.

-

Training and Technical Support: The supplier should offer thorough training on the operation and maintenance of the capsule filling machine. Additionally, ongoing technical support is essential for addressing any operational challenges. Whether it’s dealing with inert substances or optimizing the machine for various excipients, the right training and support can make a significant difference.

-

Reputation and Research: Conduct thorough research and evaluate the supplier’s reputation within the industry. Consider reaching out to past customers, reading reviews they’ve written, and assessing the longevity and stability of the supplier’s business. Too many promising businesses have faced challenges due to partnering with unreliable suppliers.

-

Sales Assistance: A dedicated sales assistant can provide personalized advice and insights based on your specific needs. From discussing the benefits of bulk quotes frequently bought to navigating the complexities of adding certain substances to your capsules, a knowledgeable sales assistant is invaluable.