15 Mar A Closer Look at Pharmaland Capsule Filling Machines

Introduction

In the intricate world of pharmaceutical and nutraceutical manufacturing, the significance of capsule filling machines cannot be overstated. These devices play a pivotal role in ensuring the efficient, precise, and safe packaging of medicines in capsule form. This article delves into the technology that powers these machines, explores the various types available, and offers insights into selecting the right machine for specific production needs.

Understanding Capsule Filling Machines

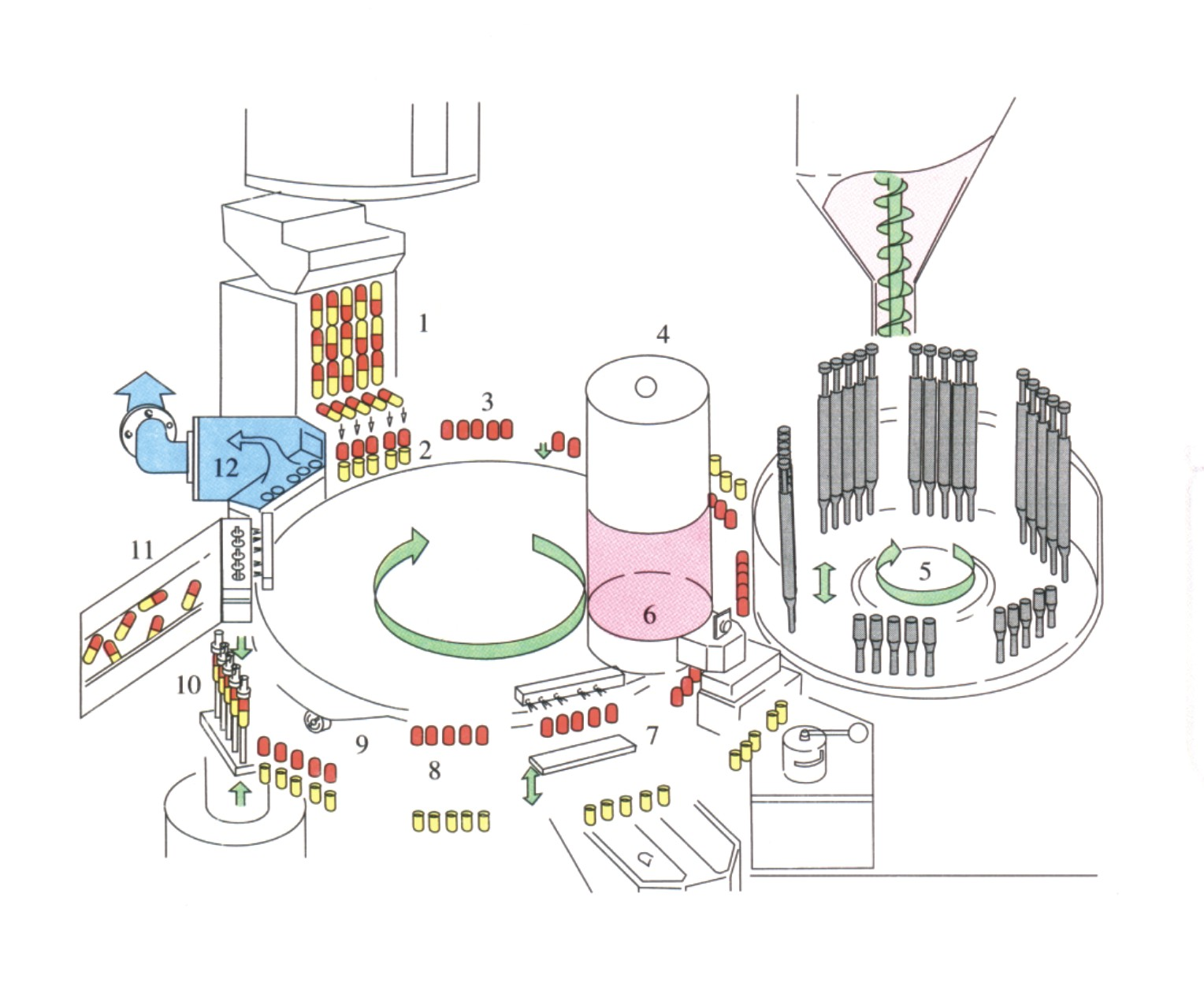

Capsule filling machines are sophisticated devices designed to fill empty capsules with pharmaceutical or nutraceutical products. From their inception to the present day, these machines have undergone significant evolution, incorporating advanced technologies to meet the stringent requirements of modern medicine production. Central to their operation are mechanisms for separating capsule halves, precise dosing of fill materials, and rejoining the halves before final packaging.

Technology Behind Capsule Filling Machines

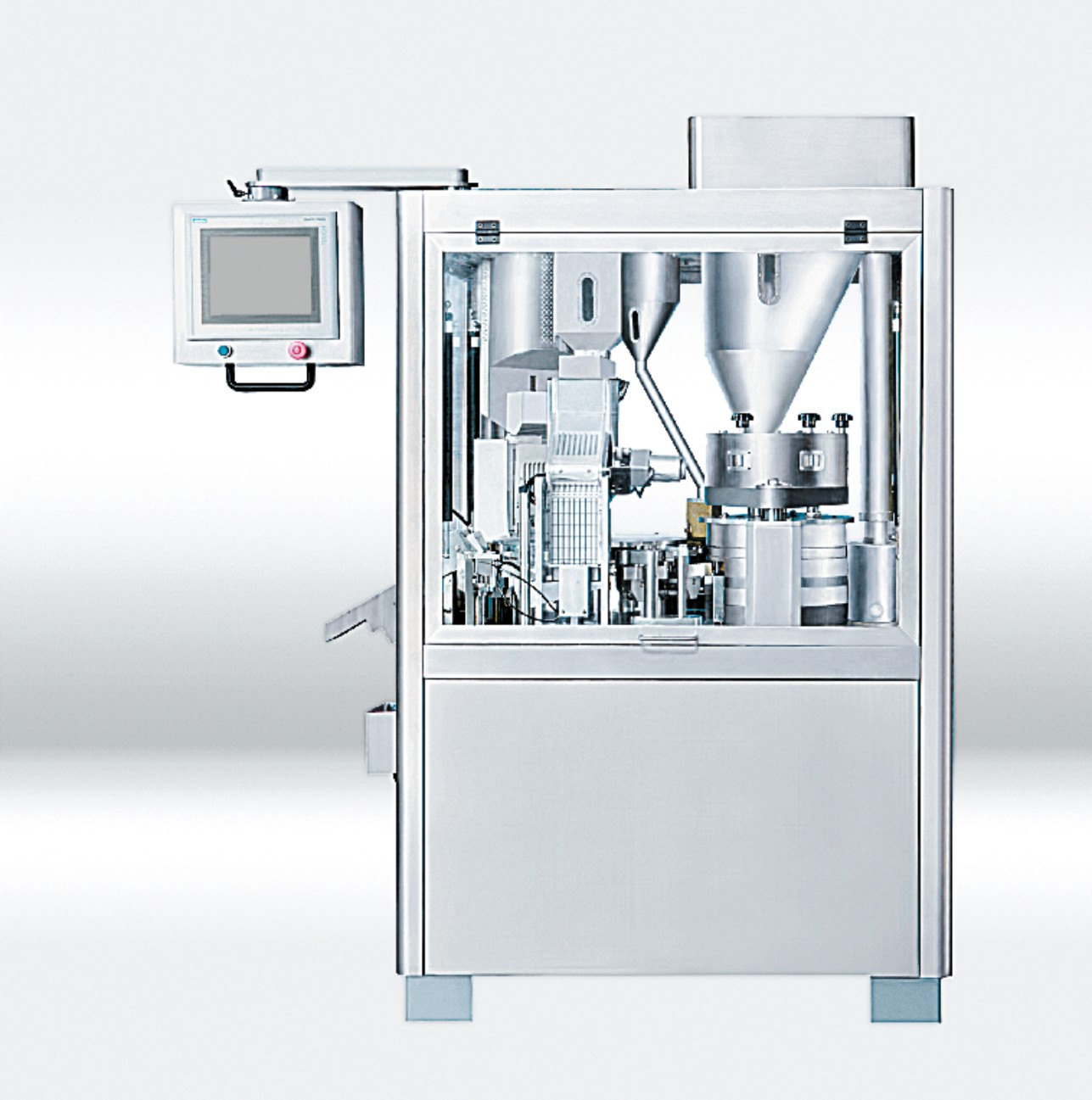

Modern capsule filling machines, like the PCF Series offered by PAG Pharmaland, integrate state-of-the-art technologies to ensure operational efficiency, precision, and compliance with Good Manufacturing Practices (GMP). These machines are constructed from high-quality stainless steel, ensuring durability and compliance with health standards. Automation plays a crucial role, with options ranging from semi-automatic to fully-automatic operations, facilitating scalability and flexibility in production processes.

Types of Capsule Filling Machine

The market offers a spectrum of capsule filling machines, categorized mainly by their operational capacities and automation levels. For instance, the PCF Series ranges from the PCF-200A, capable of handling 200 capsules per minute, to the PCF-3500, which can manage up to 3500 capsules per minute. This versatility ensures that there is a machine suited to every scale of production, from small-scale specialty batches to large-scale commercial runs. Notably, these machines can accommodate a wide range of capsule sizes and are adept at handling various filling materials, including powders, granules, and pellets.

Choosing the Right Capsule Filling Devices

Selecting the most appropriate capsule filling machine for your operation depends on several factors. These include the types of capsules to be filled, the nature of the filling material, and the required production capacity. It is also important to consider the machine’s quality assurance features, such as its capability to maintain high capsule acceptability rates and precise dosing with minimal product loss. Furthermore, the reputation of the manufacturer, their customer service, and support infrastructure are crucial considerations. Pharmaland Technologies, for example, is renowned for its high-quality machines, extensive after-sales service, and a global footprint that underscores its reliability and expertise in the field.

Capsule Machines and Their Application in the Pharmaceutical Packaging Industry

Capsule machines are indispensable in the pharmaceutical packaging industry, offering an efficient and accurate means to fill various types of capsules, including gelatin capsules, vegetarian capsules, and halal capsules. These machines can handle a wide range of fill materials, from supplement powders to powdered herbs, suitable for a variety of fillable capsules.

Automatic vs. Manual Capsule Fillers

Capsule filling machines on the market are divided into automatic capsule fillers and manual capsule filler. Automatic capsule fillers provide a solution for large-scale production by increasing operation speed, while manual capsule fillers are suitable for small-scale production or personal use, especially for regular supplement takers, offering an affordable way to meet their needs.

Choosing the Correct Capsule Size and Understanding How Much Powder

Understanding “how much powder” can be filled into a capsule is a key part of using a capsule machine. The choice of capsule size depends on the intended dosage and the type of capsule, such as gelatin caps or others. Accurate dosing ensures consistency in each capsule, which is critical for the success of the entire process.

Technological Advances in Capsule Machines

With technological advancements, the operation speed and accuracy of capsule filling machines have significantly improved. These advances not only make the production process more efficient but also enhance the overall quality of pharmaceuticals and supplements. For businesses looking to increase operation speed, investing in advanced automatic capsule filling equipment is key to boosting productivity and meeting market demand.

Additional Considerations For Capsule Filler

When investing in a capsule filling machine, it’s also wise to evaluate auxiliary features and services. Warranty terms, the availability of technical support, and customization options can significantly impact the overall value and utility of the machine. Proper training and support for installation and commissioning are essential for ensuring that the machine operates at its best from the outset. Regular maintenance and care are key to sustaining the machine’s performance and longevity.

Capsule machines play a vital role in today’s pharmaceutical packaging industry. They not only improve production efficiency and accuracy but also meet the diverse needs of consumers by providing capsule options suitable for various lifestyles and dietary habits, such as vegetarian and halal capsules. Choosing the right capsule filler, whether automatic or manual, involves considering the intended production volume, types of capsules, and fill materials. As technology continues to evolve and the market changes, the use and optimization of capsule machines will continue to play a critical role in the pharmaceutical and supplement industries.

Conclusion

The advent of pill makers, particularly automatic capsule fillers, has significantly revolutionized the health product manufacturing sector and empowered individuals to create their own supplements. These innovative machines cater to both large-scale health product manufacturers aiming for high production and individuals or small businesses who are regular supplement takers or producers.

Capsule filling machines are indispensable in the pharmaceutical and nutraceutical industries, where they contribute to the efficient, safe, and precise production of capsule-based products. The choice of the right machine involves careful consideration of technology, types, and specific production needs. By focusing on quality, reliability, and the support offered by manufacturers like Pharmaland Technologies, businesses can ensure they invest in a solution that meets their requirements and supports their long-term success.