11 Mar All You Need to Know About Capsule Filler Machines

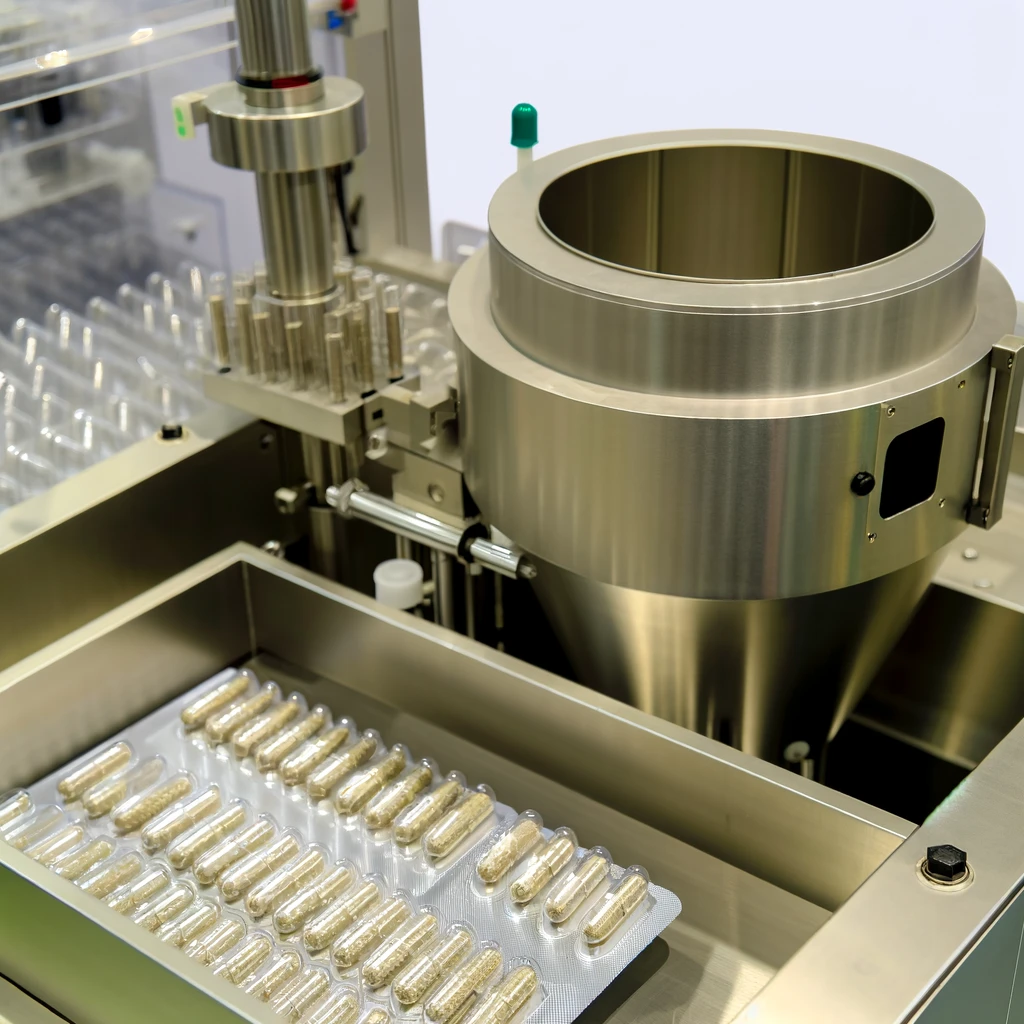

Capsule Filler

Have you ever dreamed of creating your own capsules with personalized blends and dosages? A capsule filler machine can make that dream a reality, allowing you to take control of your health and wellness. In this blog post, we will discuss the factors to consider when choosing the right machine, the benefits of owning one, top features to look for, and the differences between vegetarian and gelatin capsules. Let’s embark on this journey to unlock the world of capsule making!

Key Takeaways

- When selecting a capsule filler machine, consider size compatibility, capacity and efficiency, intended use and versatility.

- Owning a capsule filler machine provides cost savings, customization and convenience for supplement users.

- Look for features such as ease of use, durability & quality. Cleanliness & hygiene when choosing the right type of capsules (vegetarian vs gelatin).

Choosing the Right Capsule Filler Machine

A multitude of factors should be considered when choosing a capsule filler machine:

- Size compatibility: Ensure that the machine is compatible with the size of capsules you intend to use.

- Capacity and efficiency: Consider the machine’s capacity to fill capsules efficiently and in a timely manner.

- Intended use and versatility: Determine if the machine is suitable for your specific needs, such as filling different types of capsules or handling various materials.

Considering these factors will help you make a well-informed choice and kick-start your capsule creation journey.

Whether you’re a health enthusiast looking to create custom supplements or a business owner seeking to expand your product line, there’s a capsule filler machine designed to meet your needs.

Size Compatibility

One of the most important factors to consider when selecting a capsule filler machine is its size compatibility. The machine should be able to accommodate the desired capsule size to ensure accurate filling and sealing. For example, Our capsule filler is compatible with sizes:

- 000#

- 00#

- 0#

- 1#

- 2#

- 3#

- 4#

- 5#

Our service provides you with the flexibility to create customized capsules with ease, all while enjoying fast shipping.

Should you come across size compatibility issues, verifying the size of both the capsule and the product in question is a necessary step to confirm their compatibility. If they’re not, consider using a different size capsule or adjusting your formulation to avoid discrepancies.

Capacity and Efficiency

Another critical factor to consider is the machine’s capacity and efficiency. The capacity of a capsule filler machine indicates the number of capsules it can fill per day or hour, while efficiency is a key factor that affects productivity. For instance, one model of Machine has a capacity of 24 capsules, while the other semi-automatic capsule filling machine can fill up to 100 capsules at a time, accommodating 7 different sizes of capsules.

Recognizing the scale of production you aim for plays a vital role when it comes to choosing a capsule filler machine. A machine with a higher capacity will increase efficiency and save time, allowing you to focus on growing your business or enjoying the benefits of your custom-made capsules.

Intended Use and Versatility

Evaluating the versatility and suitability of a capsule filler machine for your intended use is a necessary step during the selection process. a manual capsule filler, for example, has been upgraded to reduce medication waste by 20% and increase operation speed by 20%, making it an excellent option for those who prioritize efficiency. Conducting a test of the machine’s capabilities can further ensure its suitability for your needs.

Consider whether you plan to use the machine for personal or commercial purposes. Some machines are designed specifically for either powder or liquid filling, while others can accommodate both. Knowing the intended use of the machine will help you make the best investment and ensure that it meets your expectations.

The Benefits of Owning a Capsule Filler Machine

Owning a capsule filler machine offers numerous benefits, such as:

- Cost savings: can save up to 58%

- Customization: With a capsule filler machine, you have full control over the ingredients and dosage of your supplements.

- Convenience: You can easily fill capsules at home, eliminating the need to purchase pre-made supplements.

The following subsections will delve into these benefits in greater depth.

Cost Savings

One of the most significant advantages of owning a capsule filler machine is the potential for substantial cost savings. By purchasing powder and filling your own capsules, costs can be as low as 6 cents per capsule, compared to the higher prices of pre-filled capsules.

In addition to the savings on capsule production, investing in a semi-automatic or automatic capsule filling machine can enhance pharmaceutical production processes and decrease labor costs. With these cost savings, you can allocate resources to other aspects of your business or personal wellbeing.

Customization

Another benefit of owning a capsule filler machine is the ability to create custom blends and dosages to suit your individual needs and preferences. Customization allows you to control the ingredients and their proportions, ensuring that your capsules contain the exact components and dosages you require.

Whether you’re catering to specific dietary requirements or aiming for a specific health goal, a capsule filler machine gives you the freedom to craft the perfect capsules tailored to your needs. No more settling for off-the-shelf solutions that may not fully align with your preferences or requirements.

Convenience and Time-Saving

Capsule filler machines offer convenience and time-saving benefits, including:

- Automating the capsule filling process, reducing the need for manual labor

- Increasing productivity by filling multiple capsules simultaneously

- Providing a significant time-saving advantage compared to hand-filling

Moreover, capsule filler machines offer the following benefits:

- Precision and consistency in the filling process, ensuring that each capsule contains the exact dosage required for your needs

- Increased accuracy and efficiency, allowing you to focus on other aspects of your life or business

- Assurance that your capsules are of the highest quality

Top Features to Look for in a Capsule Filler Machine

It’s important to take into account the top features that will guarantee an efficient capsule-making experience when choosing a capsule filler machine.

This section will highlight the significance of ease of use, durability, quality, cleanliness and hygiene, steering your search towards the ideal capsule filler machine.

Ease of Use

Searching for a capsule filler machine with a user-friendly design and clear instructions is an essential aspect of the selection process. A machine that is easy to operate and understand reduces the learning curve and allows you to start creating your own capsules with minimal hassle.

It’s essential to ensure that the machine has explicit instructions and a user-friendly interface, making it simple to comprehend and operate. Reading customer reviews can also provide valuable insights into the ease of use of a particular machine, helping you make an informed decision.

Durability and Quality

Choosing a machine constructed from high-quality materials is a necessary step to guarantee its durability and reliability. Stainless steel and aluminum are robust and dependable materials commonly used in the construction of capsule filler machines, while plastic is often employed for components that do not require a great deal of strength.

When selecting a machine, review the manufacturer’s warranty and customer reviews to guarantee the product’s quality. Investing in a durable and well-constructed machine will save you time and money in the long run, as it will require fewer repairs and replacements.

Cleanliness and Hygiene

Maintaining cleanliness and hygiene is vital for capsule filler machines to prevent cross-contamination and guarantee optimum efficiency. Selecting a machine with easy-to-clean components is crucial to maintaining hygiene during the capsule-making process.

It’s recommended to clean the machine regularly with a nylon brush or air pump in room-temperature water, avoiding hot water. Dust should be carefully removed from the machine, and parts can be vacuumed. By maintaining cleanliness, you can prevent potential health risks and ensure the highest quality capsules.

Types of Capsules: Vegetarian vs. Gelatin

When creating your own empty capsules, it’s important to consider the type of capsule that best suits your needs and preferences.

This section provides a comparison between vegetarian and gelatin capsules, assisting you in making the right choice.

Vegetarian Capsules

Vegetarian capsules are composed of plant-based materials, such as cellulose, and are an ideal choice for individuals with dietary restrictions or those who prefer not to consume animal byproducts. They offer numerous benefits, including:

- Faster dissolution rate

- Greater tolerance for heat and humidity than gelatin capsules

- Compatibility with automatic filling machines for increased productivity

- The same quality as gelatin capsules without the use of animal products

Common types of vegetarian capsules are cellulose and HPMC (hydroxypropyl methylcellulose). To ensure successful operation of a capsule filler machine with vegetarian capsules, follow proper setup and calibration procedures, maintain the machine regularly, and address any common issues that may arise.

Gelatin Capsules

Gelatin capsules, on the other hand, are made from animal-derived materials such as beef or pork. They are more commonly used and cost-effective than vegetarian capsules, offering several advantages like easier ingestion and quicker dissolution in the stomach for faster absorption of the contents.

When selecting a gelatin capsule, consider factors such as:

- Size

- Shape

- Color

- Contents

- Desired release rate

Gelatin capsules are a suitable choice for those without dietary restrictions and can provide similar benefits to vegetarian capsules at a lower cost.

Choosing the Right Capsule Type

When making a decision between vegetarian and gelatin capsules, consider factors like:

- Personal preferences

- Dietary needs

- Cost

- Availability

Gelatin capsules are more widely available and cost-effective, while vegetarian capsules cater to those with dietary restrictions.

Ultimately, the choice between vegetarian and gelatin capsules will depend on your individual needs and preferences. By understanding the differences between the two types, you can make an informed decision that aligns with your health goals and capsule-making requirements.

Tips for Successfully Using a Capsule Filler Machine

Operating your capsule filler machine effectively and maintaining it properly is key to leveraging its benefits fully.

This section provides tips for successful machine usage, encompassing correct setup, regular maintenance, and troubleshooting of common issues.

Proper Setup and Calibration

Correct setup and calibration of your machine is vital for precise filling and sealing. Follow the manufacturer’s instructions and verify that all components are assembled correctly and that the settings are accurate. Also, make sure that all components are clean and free of debris before setting up and calibrating the machine.

Providing operator training is vital for the safe and effective use of the machine. Instruct operators on how to use the machine and diagnose any issues that may occur. This will ensure smooth operation and prevent potential mishaps.

Regular Maintenance

Regular maintenance is key to avoiding downtime and extending the machine’s lifespan. Here are some steps to include in your proactive maintenance schedule:

- Clean the machine with a nylon brush.

- Inspect all components that interact with the capsules for signs of damage or deterioration.

- Grease the machine regularly.

By following these steps, you can ensure that your machine stays in good working condition and can stand the test of time.

Additionally, ensure that all parts are adequately lubricated and replace any worn-out or damaged parts to avoid any problems with the machine. By maintaining your capsule filler machine, you can ensure optimal performance and prevent unexpected issues.

Troubleshooting Common Issues

Preparedness for troubleshooting common issues with your capsule filler machine is vital for its efficient operation. Some frequent issues include inconsistency in dosage uniformity, capsule shell integrity issues, and clogging.

To troubleshoot these issues, inspect the machine for any obstructions, verify that the dosage settings are accurate, and confirm that the capsules are of high quality. By addressing these common issues, you can ensure the successful operation of your capsule filler machine and enjoy the benefits of creating your own capsules.

Summary

In conclusion, owning a capsule filler machine empowers you to take control of your health and wellness by creating personalized capsules tailored to your needs and preferences. By carefully selecting the right machine, understanding the differences between vegetarian and gelatin capsules, and following best practices for operation and maintenance, you can unlock the full potential of your capsule-making journey. Embrace the power of customization and discover a world of possibilities with your very own capsule filler machine!

Frequently Asked Questions

What is a capsule filler?

A Capsule Filler is a machine used to fill empty capsules with pharmaceutical ingredients, enabling large scale and efficient pharmaceutical manufacturing.

What are the disadvantages of capsule filling machine?

Capsule filling machines have low production efficiency, with manual encapsulation machines only able to fill 10-800 capsules per cycle and produce up to 600-4000 capsules per hour, making them less efficient than semi-automatic and automatic ones.

What size capsule holds 200 mg?

Size 0 capsules can hold up to 200mg of filling and are the most commonly recommended for this dosage size.

What factors should I consider when choosing a capsule filler machine?

When selecting a capsule filler machine, be sure to consider size compatibility, capacity and efficiency, and its intended use and versatility to make an informed decision.

What is the difference between vegetarian and gelatin capsules?

Vegetarian capsules are made from plant-based materials, while gelatin capsules are derived from animal byproducts, making them two distinct types of capsules.