02 Jun Exploring the Various Types of Production Lines A Comprehensive Guide

Overview of the production lines in manufacturing

Production lines play a crucial role in the manufacturing industry, enabling efficient and streamlined processes to meet production goals. This comprehensive guide aims to explore the different types of production lines, providing insights into their characteristics, applications, advantages, and limitations. By understanding these various production line methods, businesses can make informed decisions to optimize their manufacturing operations. manufacturing industry, enabling efficient and streamlined processes to meet production goals.

In this guide, we will delve into several types of production lines, including

assembly line production, cellular manufacturing, continuous flow production, batch production, job shop production, flexible manufacturing systems (FMS), and hybrid production systems.

Each section will provide a detailed overview of the production line method, highlighting its defining features, benefits, challenges, and real-world examples of its implementation across diverse industries.

I. Assembly Line Production

A. Definition and characteristics of assembly line production

Assembly line production is a manufacturing process that involves a sequential arrangement of workstations where each workstation is responsible for performing a specific task in the production of a product. This method follows a linear flow, with the product being passed from one workstation to another until it is fully assembled. The key characteristic of assembly line production is the division of labor, where each factory worker often specializes in a specific task, resulting in increased efficiency and productivity.

B. Benefits and limitations of assembly line production

Benefits of assembly line production include:

- Increased productivity:Assembly line production allows for a higher production rate as tasks are divided among multiple workers, enabling a faster assembly process.

- Cost-effectiveness:By optimizing the workflow and reducing downtime, assembly line production can lead to lower production costs and increased profitability.

- Consistency and quality control:With standardized processes and quality checks at each workstation, assembly line production ensures consistent product quality and reduces the risk of errors or defects.

- Scalability:Assembly lines can be easily scaled up or down based on demand, allowing for flexibility in production volume.

However, there are limitations to assembly line production:

- Lack of flexibility:Assembly line production is best suited for high-volume, standardized products. It may not be as adaptable to customizations or frequent product changes.

- Worker monotony:The repetitive nature of tasks in assembly line production can lead to worker fatigue and decreased job satisfaction.

- Initial setup costs:Establishing an assembly line requires significant investment in equipment, infrastructure, and training.

C. Examples and applications in various industries

Assembly line production finds applications across various industries, including automotive, electronics, consumer goods, and manufacturing. Examples include automobile final assembly plants, electronic device manufacturing facilities, and food processing lines.

II. Cellular Manufacturing

A. Explanation of cellular manufacturing concept

Cellular manufacturing is a production approach that organizes workstations into self-contained units, known as cells, where each cell is responsible for producing a specific set of products or components. This concept emphasizes the grouping of machines, equipment, and personnel based on their function or product specialization within a cell. The goal of cellular manufacturing is to increase efficiency, reduce waste, and enhance product quality by promoting teamwork, quick response times, and streamlined processes.

B. Advantages and disadvantages of cellular manufacturing

Advantages of cellular manufacturing include:

- Improved productivity:Cells are designed for specific tasks, resulting in better workflow, reduced material handling, and shorter lead times.

- Enhanced flexibility:Cells can be easily modified or reconfigured to accommodate changes in product demand or design variations, allowing for greater adaptability in a dynamic manufacturing environment.

- Enhanced quality control:With dedicated cells and focused teams, it is easier to monitor and control quality at each stage of production, leading to fewer defects and higher product reliability.

- Increased employee involvement:Cellular manufacturing encourages employee empowerment and engagement, as workers have ownership over their specific cell’s performance and are involved in decision-making processes.

Despite its benefits, cellular manufacturing also has some limitations:

- Initial setup costs:Implementing cellular manufacturing may require significant investment in reorganizing the layout, acquiring specialized equipment, and providing training for workers.

- Interdependence of cells:The efficiency of cellular manufacturing depends on the smooth coordination and synchronization between different cells. Any disruption in one cell can impact the overall production flow.

C. Real-world examples of cellular manufacturing implementation

Real-world examples of cellular manufacturing implementation can be found in industries such as automotive manufacturing, electronics assembly, and aerospace. These industries leverage cellular manufacturing to achieve higher productivity, faster response times, and improved product quality.

III. Continuous Flow Production

A. Definition and features of continuous flow production

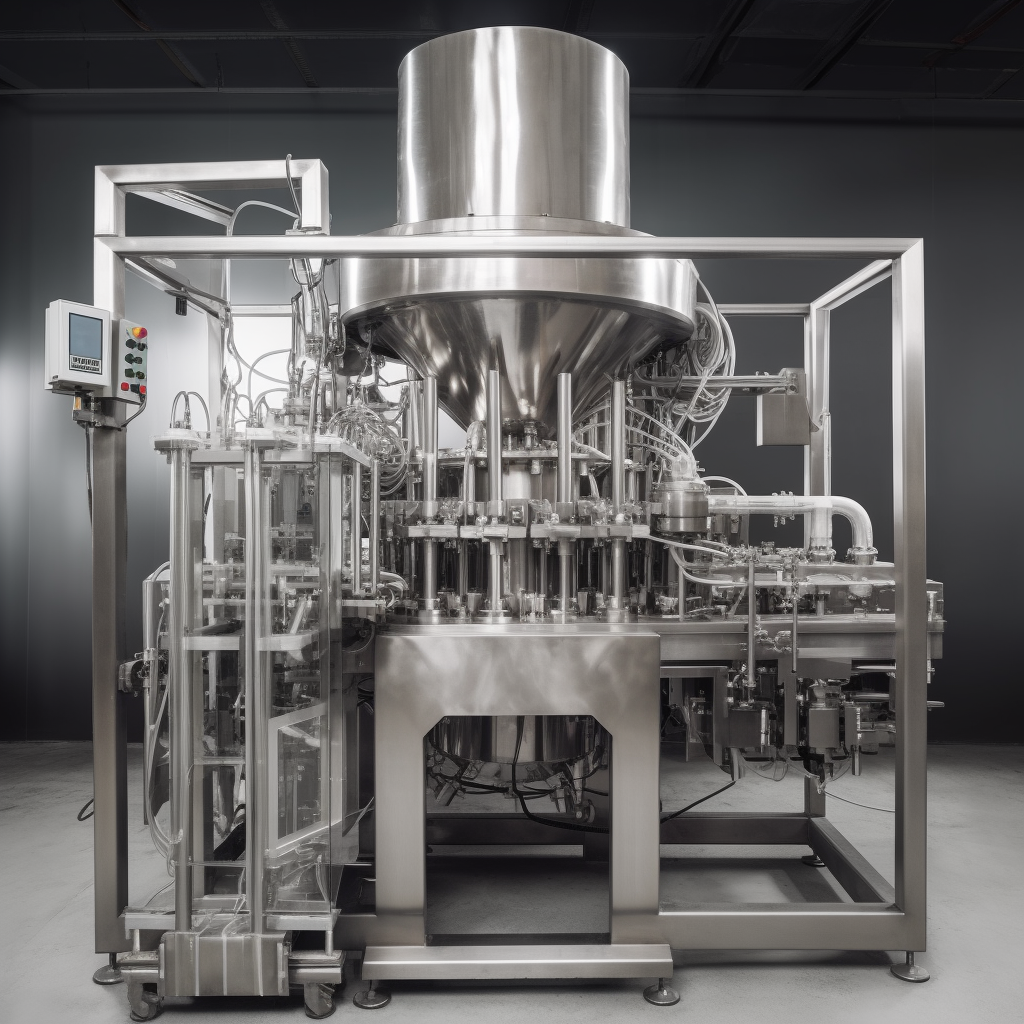

Continuous flow production, also known as mass production or flow manufacturing, is a production method that focuses on the continuous movement of products through the manufacturing process. It involves a constant flow of materials and components, with minimal interruptions or delays. Continuous flow production is characterized by its high efficiency, standardized processes, and emphasis on automation.

Continuous flow production is characterized by the following features:

- Uninterrupted production:The production process operates continuously, with a steady flow of materials and products.

- Standardized processes:The manufacturing processes are carefully designed and standardized to ensure consistency and efficiency.

- High volume output:Continuous flow production is suitable for producing large quantities of identical or similar products.

- Automation:Machinery and equipment play a crucial role in continuous flow production, as automation is often utilized to achieve high-speed and precise operations.

B. Key principles and techniques used in continuous flow production

- Just-in-Time (JIT) production:JIT is a principle that aims to minimize inventory levels by producing and delivering components or products as they are needed in the production process.

- Kanban system:The Kanban system is a visual signaling system that controls the flow of materials and components in a continuous production line. It ensures that each workstation receives the necessary inputs at the right time.

- Line balancing:Line balancing is the process of distributing work evenly across workstations to maximize efficiency and minimize bottlenecks in the production line.

- Lean manufacturing:Lean manufacturing principles, such as waste reduction, value stream mapping, and continuous improvement, are often applied in continuous flow production to optimize processes and eliminate non-value-added activities.

C. Industries where continuous flow production is commonly employed

Continuous flow production is commonly employed in industries such as:

- Automotive manufacturing:The automotive industry extensively uses continuous flow production to achieve high volumes of standardized vehicles.

- Electronics manufacturing:Continuous flow production is used in the production of electronic components, circuit boards, and consumer electronics.

- Food and beverage manufacturing:Many food and beverage products, such as beverages, snacks, and packaged goods, are produced using continuous flow production methods.

- Pharmaceutical manufacturing:Continuous flow production is employed in pharmaceutical manufacturing for high-volume production of medications and pharmaceutical products.

IV. Batch Production

A. Overview of batch production methodology

Batch production is a manufacturing method where products are produced in groups or batches, with each batch going through the production process as a distinct unit. It involves the sequential processing of a set quantity of materials or components before moving on to the next batch. Batch production is commonly used when there is a need to produce different products or variations of a product in limited quantities.

Batch production follows the following methodology:

- Planning:The production schedule is carefully planned to determine the quantity and sequence of each batch.

- Set-up:The production line is prepared and set up according to the specifications of the batch.

- Processing:The materials or components required for the batch are collected, and the production process is carried out in a sequential manner.

- Quality control:Each batch is subjected to quality checks and inspections to ensure adherence to specifications and standards.

- Cleaning and changeover:Once a batch is completed, the equipment and production line are cleaned and prepared for the next batch.

B. Advantages and challenges of batch production

Advantages of batch production include:

- Flexibility: Batch production allows for the production of different products or variations in response to customer demands.

- Cost-effectiveness: Batch production can be more cost-effective than continuous production for smaller production volumes.

- Quality control: Each batch can be thoroughly inspected and tested, ensuring higher quality standards.

Challenges of batch production include:

- Changeover time: Switching between different batches requires time for cleaning, setup, and changeover, which can impact production efficiency.

- Inventory management: Batch production may result in higher inventory levels due to the need to produce in batches and store finished goods.

C. Case studies illustrating the use of batch production

Several industries utilize batch production methods, including:

- Food and beverage: The production of baked goods, sauces, and beverages often follows batch production processes to accommodate recipe variations and ensure quality control.

- Pharmaceuticals: Pharmaceutical manufacturing frequently employs batch production for drug formulations, allowing for precise control and monitoring of ingredients.

- Cosmetics: Batch production is used in the cosmetics industry to produce different shades and variations of skincare and makeup products.

- Chemicals: Batch production is common in the production of specialty chemicals, where different formulations and compositions are required for specific applications.

V. Job Shop Production Line

A. Definition and characteristics of job shop production

Job shop production is a manufacturing approach characterized by the production of custom-made or unique products tailored to meet specific customer requirements. In job shop production, each order or job is treated as a separate entity, and the production process is designed to accommodate the individual needs of each job.

Job shop production exhibits the following characteristics:

- Customization: Products are customized according to the specific requirements of each customer. This often involves varying designs, specifications, and materials.

- Variety of operations: Job shop production involves a wide range of operations and processes to accommodate the diverse needs of different jobs.

- Low volume, high variety: Job shop production is characterized by producing small quantities of a wide variety of products.

B. Key considerations and challenges in job shop production

Job shop production presents several considerations and challenges, including:

- Production scheduling: Coordinating and scheduling jobs to optimize resource utilization and minimize lead times can be complex due to the varying requirements of each job.

- Resource allocation: Allocating resources, such as equipment, labor, and materials, in an efficient and cost-effective manner is crucial to meet the unique demands of each job.

- Workflow management: Managing the flow of materials and information through the production process becomes challenging due to the customization and variability of jobs.

C. Examples of industries that rely on job shop production

Various industries rely on job shop production, including:

- Custom manufacturing: Industries involved in producing made-to-order products, such as customized furniture, specialty machinery, and tailor-made clothing, heavily rely on job shop production.

- Fabrication and machining: Metal fabrication shops and machining facilities that produce custom parts or components based on customer specifications often employ job shop production.

- Printing and packaging: Printing companies that offer customized printing services, such as personalized labels, packaging materials, and promotional items, utilize job shop production.

- Automotive repair and customization: Auto body shops and custom car shops that provide repair, restoration, and customization services follow a job shop production approach to meet the unique needs of each vehicle.

VI. Flexible Manufacturing Process

A. Introduction to flexible manufacturing systems (FMS)

Flexible Manufacturing Systems (FMS) refer to highly automated production systems that are capable of adapting to changing production requirements and producing a wide range of products. FMS combines computer-controlled machines, robots, and material handling systems to create a versatile and efficient manufacturing environment.

B. Features and benefits of FMS

Flexible Manufacturing Systems offer several features and benefits, including:

- Versatility: FMS can handle various product designs and specifications, allowing manufacturers to quickly switch between different products or customize products to meet specific customer demands.

- Automation: FMS utilizes advanced automation technologies, such as robotics and computer control, to perform tasks with precision, speed, and consistency. This reduces manual labor and increases overall productivity.

- Scalability: FMS can be easily scaled up or down to accommodate changes in production volume. It provides the flexibility to adjust production capacity based on market demand, improving operational efficiency and reducing costs.

- Improved Efficiency: FMS optimizes the flow of materials, reduces setup time, minimizes idle time, and eliminates bottlenecks, leading to improved production efficiency and shorter lead times.

C. Case studies showcasing the implementation of FMS

Several industries have successfully implemented Flexible Manufacturing Systems. For example:

- Automotive Industry: Automotive manufacturers have integrated FMS to streamline production processes, enabling efficient assembly of different vehicle models on the same production line. This allows for faster production changeovers and customization options for customers.

- Electronics Industry: Electronics manufacturers utilize FMS to produce a wide range of electronic devices, such as smartphones and computers. FMS enables rapid product variations and customization while maintaining high-quality standards.

- Aerospace Industry: Aerospace companies utilize FMS to manufacture complex components and assemblies with high precision. FMS enables efficient production of diverse aircraft parts, reducing lead times and ensuring quality control.

VII.Hybrid Production Systems

A. Explanation of hybrid production systems

Hybrid Production Systems combine elements of different production methodologies to create a flexible and efficient manufacturing approach. It integrates the strengths of multiple production systems, such as assembly line, batch production, and job shop, to optimize production processes and meet diverse customer demands.

B. Advantages and challenges of hybrid production systems

Hybrid Production Systems offer several advantages, including:

- Flexibility: Hybrid systems allow manufacturers to adapt to changing production requirements and accommodate a wide range of product variations. This flexibility enables quick customization and response to market demands.

- Efficiency: By incorporating different production methodologies, hybrid systems optimize resource utilization, minimize idle time, and improve overall productivity. They streamline production processes and reduce production lead times.

- Cost-effectiveness: Hybrid systems optimize the use of resources, including equipment, labor, and materials, resulting in cost savings. They enable manufacturers to balance efficiency and cost considerations effectively.

However, implementing hybrid production systems also comes with challenges, such as:

- Complexity: Integrating multiple production methodologies requires careful planning, coordination, and synchronization. Managing the interplay between different systems can be complex and requires efficient communication and control mechanisms.

- Skill Requirements: Hybrid systems often require a diverse set of skills and expertise to operate and maintain various production processes. Ensuring a skilled workforce and providing appropriate training are essential for successful implementation.

C. Examples of industries leveraging hybrid production process

Various industries leverage hybrid production systems to enhance their manufacturing capabilities. Some examples include:

- Consumer Electronics Industry: Manufacturers of smartphones, tablets, and other electronic devices utilize hybrid production systems to achieve a balance between mass production and customization. This enables them to efficiently produce a wide range of products while catering to individual customer preferences.

- Food and Beverage Industry: Companies in the food and beverage sector leverage hybrid production systems to optimize their production processes. They combine continuous flow production for high-volume items with batch production for seasonal or customized products, allowing for efficient production and flexibility in product offerings.

- Pharmaceutical Industry: Pharmaceutical manufacturers utilize hybrid production systems to accommodate the production of different drug formulations and dosages. They integrate batch production for small-scale, specialized medications with continuous flow production for high-demand products, ensuring both efficiency and flexibility.

In this comprehensive guide, we explored various types of production lines. We discussed assembly line production, cellular manufacturing, continuous flow production, batch production, job shop production, flexible manufacturing systems (FMS), hybrid production systems, and their characteristics. Each production line offers unique advantages and considerations based on the specific requirements of different industries.

When selecting the appropriate production line for a specific manufacturing process, several factors need to be considered. These include production volume, product complexity, customization requirements, resource utilization, efficiency, cost-effectiveness, and flexibility. It is crucial to evaluate these factors carefully to ensure the chosen production line aligns with the organization’s goals and objectives.

The field of production line technology is continuously evolving, driven by advancements in automation, robotics, artificial intelligence, and data analytics. Future trends include the integration of smart manufacturing technologies, the adoption of Industrial Internet of Things (IIoT) systems, and the implementation of advanced analytics for real-time production monitoring and optimization. Additionally, sustainable manufacturing practices, such as eco-friendly materials and energy-efficient processes, are gaining prominence in the industry.